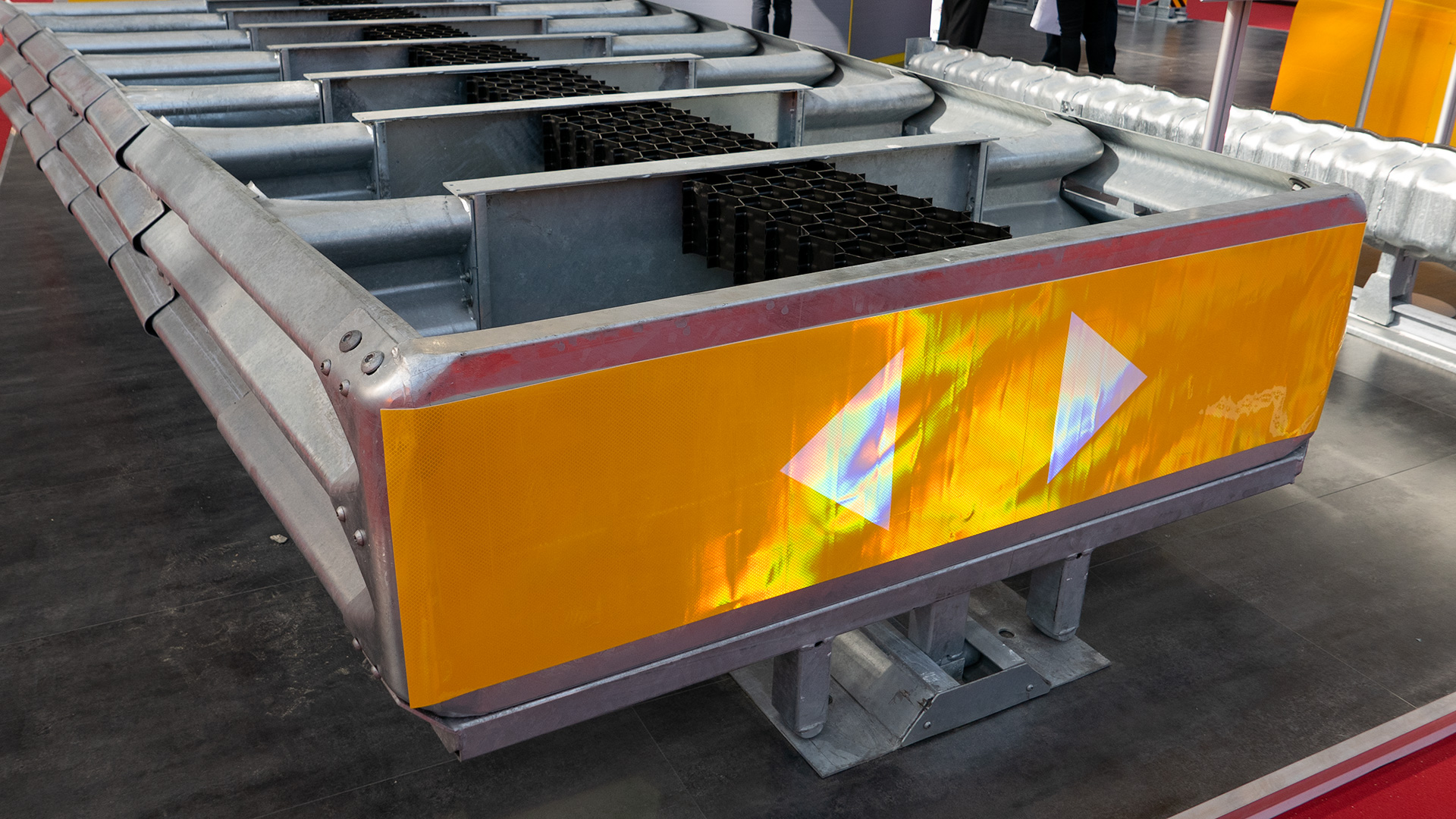

New space-saving crash cushion concept

The installation can be anchored directly on road surface with no need for extra anchors, that make the safety measure easy to install. In case of collision, most of the structure of the cushion can be reused and there is only need for a limited supply of spare parts.

The base structure is completely in electro-welded steel, made of 5/6 mm thick plate and monorail guide for the sliding bars linked to retaining panels of the absorbing cells.

The bumper or frontal panel is the rigid connection among the sliding side panels which slide one upon the other after the impact, driven by an appropriate shift system. At the same time the central panels which are connected to a couple of sliding side panels, crash the cells gradually dissipate the kinetic energy generated by the impact. The additional panels help the redirecting of the vehicle, by absorbing the energy of the lateral impact.

Automation Manufacturing Services ltd. says it is the safest crash cushion in the world on basis of the solution is fully compliant with European Normative EN1317 and the American Standard NCHRP 350. The product is the only crash cushion tested at 130 kph and is the first crash cushion with 5 Stars EuroNcap Certification.

Impressive solution with promising qualities for a demanding environment like a road tunnel.

Read more: http://www.smaroadsafety.com/en

En

En